How SiC and GaN Are Transforming High-Power Electronics

1/15/2025 5:56:26 PM

The global shift toward electrification-spurred by renewable energy adoption, electric vehicles (EVs), and 5G infrastructure-has created an urgent need for more efficient, compact, and heat-resistant power electronics. Traditional silicon (Si)-based semiconductors, long dominant in this space, are reaching their physical limits in high-voltage and high-frequency applications. Enter wide-bandgap (WBG) semiconductors like silicon carbide (SiC) and gallium nitride (GaN), materials that are rewriting the rules of power conversion. This article explores how these revolutionary materials are enabling breakthroughs in energy efficiency, driving innovation across industries, and shaping the future of sustainable technology.

The Limitations of Silicon in High-Power Scenarios

Silicon has been the backbone of power electronics for decades, but its relatively narrow bandgap (1.12 eV) imposes critical limitations:

Energy Loss: At voltages above 600V, silicon MOSFETs and IGBTs suffer from significant conduction and switching losses, wasting up to 30% of energy in industrial drives and EV inverters .

Size and Heat Management: High power densities require bulky heat sinks and cooling systems, increasing weight and cost-especially problematic for EVs, where every kilogram impacts battery range.

Frequency Constraints: Silicon devices operate efficiently below 20 kHz, restricting their use in high-frequency applications like wireless charging and renewable energy inverters .

Wide-bandgap materials address these challenges with superior properties: SiC (3.26 eV) and GaN (3.4 eV) offer 3x higher breakdown electric field, 10x better thermal conductivity, and 2x higher electron saturation velocity than silicon . This allows them to handle higher voltages (up to 10 kV for SiC), switch faster (up to 100 MHz for GaN), and operate at temperatures exceeding 200°C-transforming high-power systems.

Key Technological Advancements

1. Silicon Carbide: The EV Game-Changer

SiC has emerged as a cornerstone of electric vehicle technology, particularly in traction inverters. Tesla's Model 3 was among the first to adopt SiC MOSFETs, achieving a 50% reduction in inverter size and a 10% increase in battery range per charge . Modern SiC devices now enable:

99% Efficiency in DC-DC Conversion: NXP's latest SiC-based converter for EV on-board chargers reduces energy loss to just 1%, critical for maximizing battery utilization .

High-Temperature Reliability: Rohm's 1200V SiC modules operate stably at 175°C, eliminating the need for liquid cooling in auxiliary systems and reducing vehicle weight by 5 kg .

Beyond EVs, SiC is revolutionizing renewable energy. Solar inverters using SiC diodes achieve 98.5% efficiency, enabling an additional 5% energy harvest compared to silicon-based systems . This efficiency gain is pivotal for offsetting the intermittency of wind and solar power.

2. Gallium Nitride: Enabling High-Frequency Innovation

GaN's strengths lie in high-frequency, low-voltage applications (below 600V), making it ideal for consumer electronics and 5G infrastructure:

Ultra-Fast Charging: GaN-based chargers like Navitas Semiconductor's NV6117 deliver 100W of power in a 3cm³ package-50% smaller than silicon alternatives-enabling smartphone chargers that refill 50% battery in 15 minutes .

5G Power Amplifiers: Qorvo's GaN-on-silicon power amplifiers boost data transmission efficiency by 40% in 5G base stations, reducing energy consumption and cooling costs for telecom operators .

Wireless Power Transfer: At 6.78 MHz, GaN devices enable efficient charging over longer distances (up to 1 meter), a critical feature for electric vehicle inductive charging and smart home ecosystems .

3. Material and Process Innovations

Monolithic Integration: Researchers at MIT have developed a technique to grow GaN directly on silicon substrates, eliminating the need for expensive sapphire or silicon carbide bases and reducing production costs by 60% .

3D Packaging for SiC: Wolfspeed's 3D-stacked SiC dies increase power density by 3x, allowing 10kW chargers to fit in a space previously occupied by 3kW silicon-based units .

Enhanced Thermal Management: Sandia National Laboratories' nanocomposite thermal interface materials improve heat dissipation from SiC modules by 25%, enabling compact designs for aerospace applications .

Industry Impact and Market Trends

1. Economic and Environmental Synergies

The WBG semiconductor market is growing exponentially, projected to reach $27 billion by 2029 with a CAGR of 30% . This growth is driven by:

EV Production Scaling: Each electric vehicle uses

500−

1,000 worth of SiC/GaN components, compared to $50 in internal combustion engine vehicles .

Energy Savings: A 2024 report by BloombergNEF estimates that widespread WBG adoption could save 1,200 TWh of electricity globally by 2030-equivalent to the annual output of 3,000 coal-fired power plants .

2. Challenges in Mass Adoption

Cost Barriers: SiC wafers cost 10x more than silicon due to complex manufacturing (only 50% of 150mm SiC wafers are defect-free), though economies of scale are driving prices down by 20% annually .

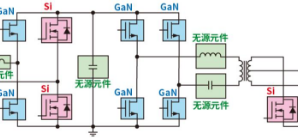

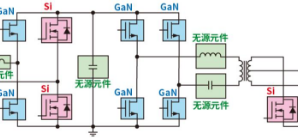

Design Complexity: High switching speeds require new circuit layouts and EMI suppression techniques, challenging engineers accustomed to silicon-based designs.

Reliability Standards: Industry-wide testing protocols for high-temperature, high-humidity environments are still evolving, slowing adoption in critical sectors like aerospace and grid infrastructure.

3. Future Frontiers

Beyond 200mm Wafers: Companies are transitioning to 200mm and 300mm SiC/GaN wafer production, doubling yields and reducing per-device costs by 35% by 2026 .

Hybrid Materials: Researchers at Tsinghua University are developing SiC-GaN heterostructures that combine the high-voltage capability of SiC with GaN's high-frequency performance, enabling versatile devices for next-gen energy grids .

Quantum Integration: GaN's piezoelectric properties make it a candidate for quantum sensor interfaces, a nascent field where precise control over nanoscale vibrations is critical.

The Road to a WBG-Driven Future

While silicon will remain dominant in low-power, logic-based applications, wide-bandgap semiconductors are poised to own the high-power, high-frequency landscape. Their ability to shrink systems, reduce energy waste, and enable new applications aligns perfectly with global sustainability goals. As governments mandate stricter emissions standards (e.g., the EU's 2035 ICE ban) and renewable energy penetration grows, the demand for SiC and GaN will only intensify.

The transition won't happen overnight-material science, manufacturing processes, and industry standards must evolve in tandem. But for an electronics sector increasingly defined by efficiency and electrification, the wide-bandgap revolution is not just a trend; it's a necessity. From powering the next generation of electric vehicles to stabilizing renewable energy grids, SiC and GaN are more than components-they're the building blocks of a smarter, greener future.

The Limitations of Silicon in High-Power Scenarios

Silicon has been the backbone of power electronics for decades, but its relatively narrow bandgap (1.12 eV) imposes critical limitations:

Energy Loss: At voltages above 600V, silicon MOSFETs and IGBTs suffer from significant conduction and switching losses, wasting up to 30% of energy in industrial drives and EV inverters .

Size and Heat Management: High power densities require bulky heat sinks and cooling systems, increasing weight and cost-especially problematic for EVs, where every kilogram impacts battery range.

Frequency Constraints: Silicon devices operate efficiently below 20 kHz, restricting their use in high-frequency applications like wireless charging and renewable energy inverters .

Wide-bandgap materials address these challenges with superior properties: SiC (3.26 eV) and GaN (3.4 eV) offer 3x higher breakdown electric field, 10x better thermal conductivity, and 2x higher electron saturation velocity than silicon . This allows them to handle higher voltages (up to 10 kV for SiC), switch faster (up to 100 MHz for GaN), and operate at temperatures exceeding 200°C-transforming high-power systems.

Key Technological Advancements

1. Silicon Carbide: The EV Game-Changer

SiC has emerged as a cornerstone of electric vehicle technology, particularly in traction inverters. Tesla's Model 3 was among the first to adopt SiC MOSFETs, achieving a 50% reduction in inverter size and a 10% increase in battery range per charge . Modern SiC devices now enable:

99% Efficiency in DC-DC Conversion: NXP's latest SiC-based converter for EV on-board chargers reduces energy loss to just 1%, critical for maximizing battery utilization .

High-Temperature Reliability: Rohm's 1200V SiC modules operate stably at 175°C, eliminating the need for liquid cooling in auxiliary systems and reducing vehicle weight by 5 kg .

Beyond EVs, SiC is revolutionizing renewable energy. Solar inverters using SiC diodes achieve 98.5% efficiency, enabling an additional 5% energy harvest compared to silicon-based systems . This efficiency gain is pivotal for offsetting the intermittency of wind and solar power.

2. Gallium Nitride: Enabling High-Frequency Innovation

GaN's strengths lie in high-frequency, low-voltage applications (below 600V), making it ideal for consumer electronics and 5G infrastructure:

Ultra-Fast Charging: GaN-based chargers like Navitas Semiconductor's NV6117 deliver 100W of power in a 3cm³ package-50% smaller than silicon alternatives-enabling smartphone chargers that refill 50% battery in 15 minutes .

5G Power Amplifiers: Qorvo's GaN-on-silicon power amplifiers boost data transmission efficiency by 40% in 5G base stations, reducing energy consumption and cooling costs for telecom operators .

Wireless Power Transfer: At 6.78 MHz, GaN devices enable efficient charging over longer distances (up to 1 meter), a critical feature for electric vehicle inductive charging and smart home ecosystems .

3. Material and Process Innovations

Monolithic Integration: Researchers at MIT have developed a technique to grow GaN directly on silicon substrates, eliminating the need for expensive sapphire or silicon carbide bases and reducing production costs by 60% .

3D Packaging for SiC: Wolfspeed's 3D-stacked SiC dies increase power density by 3x, allowing 10kW chargers to fit in a space previously occupied by 3kW silicon-based units .

Enhanced Thermal Management: Sandia National Laboratories' nanocomposite thermal interface materials improve heat dissipation from SiC modules by 25%, enabling compact designs for aerospace applications .

Industry Impact and Market Trends

1. Economic and Environmental Synergies

The WBG semiconductor market is growing exponentially, projected to reach $27 billion by 2029 with a CAGR of 30% . This growth is driven by:

EV Production Scaling: Each electric vehicle uses

500−

1,000 worth of SiC/GaN components, compared to $50 in internal combustion engine vehicles .

Energy Savings: A 2024 report by BloombergNEF estimates that widespread WBG adoption could save 1,200 TWh of electricity globally by 2030-equivalent to the annual output of 3,000 coal-fired power plants .

2. Challenges in Mass Adoption

Cost Barriers: SiC wafers cost 10x more than silicon due to complex manufacturing (only 50% of 150mm SiC wafers are defect-free), though economies of scale are driving prices down by 20% annually .

Design Complexity: High switching speeds require new circuit layouts and EMI suppression techniques, challenging engineers accustomed to silicon-based designs.

Reliability Standards: Industry-wide testing protocols for high-temperature, high-humidity environments are still evolving, slowing adoption in critical sectors like aerospace and grid infrastructure.

3. Future Frontiers

Beyond 200mm Wafers: Companies are transitioning to 200mm and 300mm SiC/GaN wafer production, doubling yields and reducing per-device costs by 35% by 2026 .

Hybrid Materials: Researchers at Tsinghua University are developing SiC-GaN heterostructures that combine the high-voltage capability of SiC with GaN's high-frequency performance, enabling versatile devices for next-gen energy grids .

Quantum Integration: GaN's piezoelectric properties make it a candidate for quantum sensor interfaces, a nascent field where precise control over nanoscale vibrations is critical.

The Road to a WBG-Driven Future

While silicon will remain dominant in low-power, logic-based applications, wide-bandgap semiconductors are poised to own the high-power, high-frequency landscape. Their ability to shrink systems, reduce energy waste, and enable new applications aligns perfectly with global sustainability goals. As governments mandate stricter emissions standards (e.g., the EU's 2035 ICE ban) and renewable energy penetration grows, the demand for SiC and GaN will only intensify.

The transition won't happen overnight-material science, manufacturing processes, and industry standards must evolve in tandem. But for an electronics sector increasingly defined by efficiency and electrification, the wide-bandgap revolution is not just a trend; it's a necessity. From powering the next generation of electric vehicles to stabilizing renewable energy grids, SiC and GaN are more than components-they're the building blocks of a smarter, greener future.